This article describes the process of dragging a pipeline through a channel. In the simulation of this process, the interactions between the pipeline, the drill rod, the soil and the bentonite mud are taken into account. Dragging of the pipeline through the well is hampered by frictional forces of the pipeline and the drill rod against the soil, as well as the drag force of the pipeline when it moves in the drilling fluid. In the construction of a mathematical model, the influence of these forces is taken into account. To determine the frictional forces, the pipeline and the drill rod were considered as a flexible non-stretch filament. An algorithm for determining the tractive effort is created and implemented. A separate stage of the work is devoted to the accounting of ballasting of the pipeline.

pulling,

pipeline,

pulling force,

horizontal directional drilling,

drilling mud,

mathematical modeling

Purpose: Create and implement an algorithm for determining the minimum tractive effort while dragging a pipeline.

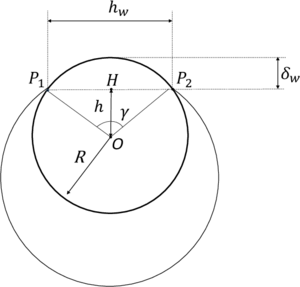

Methods: To solve this problem, we considered the resistance force exerted on the pipeline by bentonite drilling mud, the friction force of the drill rod against the soil, the frictional force of the pipeline against the soil.

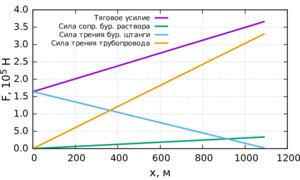

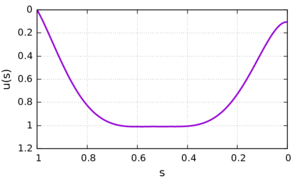

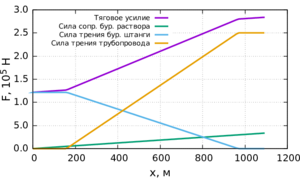

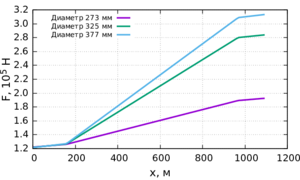

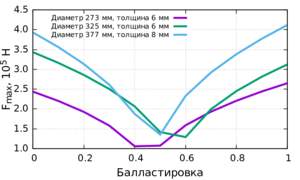

Results: As a result of the research, it was revealed that: up to the point where the pipeline and the upper wall of the bore come into contact, the greatest contribution is made by the friction force of the drill rod on the upper wall of the borehole; further, from the moment of the beginning of the contact of the pipeline and the upper wall of the well and the end of dragging the pipeline, the greatest contribution is made by the frictional force of the pipeline on the upper wall of the well; for each diameter there is an optimum degree of ballasting, at which the tractive effort is minimal.