The paper presents the results of experimental studies of the flow of stabilized water-oil emulsions prepared from oil and formation water from the wells of the West Kochevne field, as well as with the presence of chrysotile and aerosil in cylindrical and flat capillaries (in the crack patterns). The effect of dynamic blocking has been discovered, which consists in the fact that in sections of capillaries and in a model of cracks, with a constant pressure drop, the flow of reverse oil-water emulsions stops with time. An increase in the content of isotropic and anisotropic particles led to an increase in the viscosity of the emulsion and a decrease in the time of onset of dynamic blocking. With the same percentage of particles in emulsions containing chrysotile, the time of onset of blocking and the volume of leaked emulsion before blocking is an order of magnitude less than that of emulsions containing aerosil. However, in this case, the viscosity of the emulsion with aerosil is even higher than that of a similar emulsion with chrysotile.

dispersion,

emulsion,

capillary,

Hele–Show cell,

dynamic blocking

The paper presents the results of experimental studies of the flow of stabilized water-oil emulsions prepared from oil and produced water from the wells of the West Kochevne field, as well as with the presence of chrysotile and aerosil in cylindrical and flat capillaries, in the crack patterns.

Objective: to study the rheological properties and the demonstration of the effect of dynamic blocking for the three types of emulsions: invert emulsion, emulsion with aerosil and emulsion with anisotropic inclusion chrysotile.

Methods: The rheological characteristics of the emulsions were determined using a modern high-precision rheometer HAAKE MARS III using the double cone-plate measurement system.

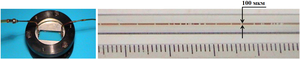

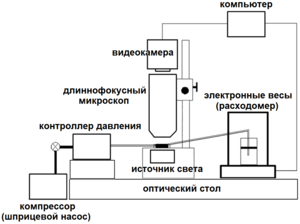

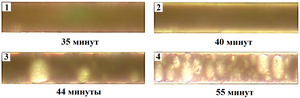

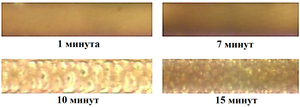

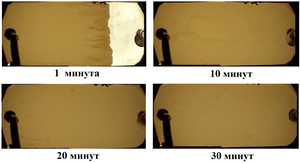

The experiments were carried out in a cylindrical glass capillary with an axisymmetric flow and a flat capillary channel (Hele-Show cell) with a forward flow. The flow was organized by supplying liquids at a pressure drop of 200 kPa to the inlet of capillary structures, the output pressure was atmospheric, the flow characteristics of the flow were measured using electronic scales HM-200 interfaced with a computer. The flow pattern was recorded on a digital video camera at the scale of the model and at a microscale using a Stemi–2000C microscope.

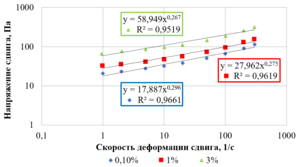

Results: When measuring rheological parameters using the cone-plate system, it was established:

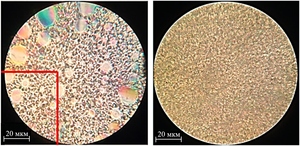

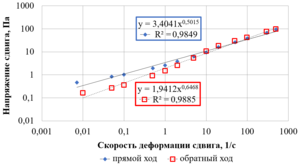

1) Rheological curves with a good degree of reliability are described by a power function, which corresponds to the model of the Ostwald de Vaale fluid. The passage of the backward curve below the forward curve is due to the lower stability of the emulsion with large drops, some of which coalesce in the shear flow, the emulsion becomes coarse and less viscous, which is typical of low concentrations of emulsifier. At high concentrations, microdroplets practically do not coalesce and the emulsion is more stable.

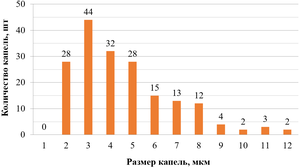

2) An increase in the concentration of the emulsifier from 1% to 4% leads to a decrease in the size of the microdroplets from 5 μm to 1 μm and an increase in the effective viscosity (for example, in the range of the shear strain rate 0.1–100, they differ by 3 times).

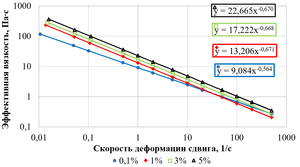

3) The addition of nanopowders leads to an increase in the viscosity of the emulsion. An increase in the concentration of chrysotile from 0.1% to 5% increased the viscosity by more than 3 times, an increase in the concentration of aerosil from 0.1% to 3% increased the viscosity by 3 times.

The addition of nanopowders leads to an increase in the viscosity of the emulsion. A change in the concentration of chrysotile from 0.1% to 5% increases the viscosity by more than 3 times, and change in the concentration of aerosil from 0.1% to 3% increases the viscosity by 3 times.

4) With aerosil isotropic nanoparticles, the emulsion is stable, the forward and reverse motion differ little. Anisotropic particles with chrysotile, a direct and reverse course differ significantly, this is due to the fact that as the cone in the shear flow rotates, the chrysotile particles line up along the streamlines, which leads to a decrease in the rheological curve.

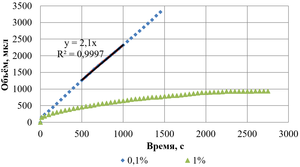

The study of the effect of dynamic blocking showed:

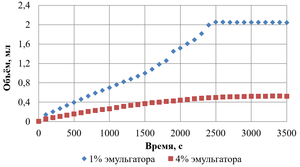

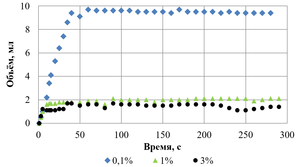

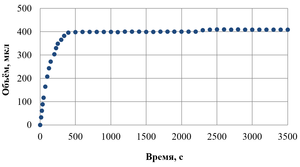

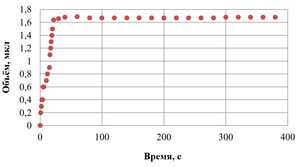

1) An increase in the content of isotropic and anisotropic particles led, in addition to an increase in viscosity, to a decrease in the time of onset of dynamic blocking.

2) With the same percentage content of particles in emulsions containing chrysotile, the time of onset of blocking and the volume of the leaked emulsion before blocking is an order of magnitude less than that of emulsions containing aerosil. However, in this case, the viscosity of the emulsion with aerosil is even higher than that of a similar emulsion with chrysotile. This can be explained by the fact that chrysotile is an anisotropic powder with a specific structure.

The results obtained in the course of experimental studies allow us to conclude that the use of reverse water–oil emulsions containing solid inclusions is effective for killing wells in fractured rocks.