Mikhaylenko C.I.

A finite volume mesh with periodic boundary conditions for a vortex tube numerical simulation. Multiphase Systems. 16 (2021) 2. 72–78.

A finite volume mesh with periodic boundary conditions for a vortex tube numerical simulation

Mikhaylenko C.I.

Mavlyutov Institute of Mechanisc UFRC RAS, Ufa, Russia

Abstract

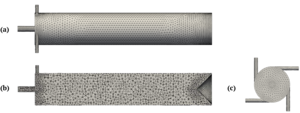

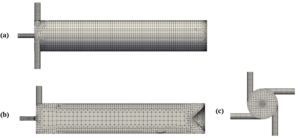

The article describes some aspects of computational modeling of air dynamics in a vortex tube channel. In particular,

possible approaches to the numerical study of various geometric parameters are considered, both for the efficiency of temperature stratification and for

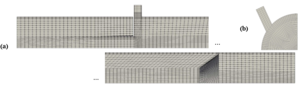

maximizing or minimizing various parameters of physical diaphragms. An approach to the choice of a method for constructing a finite-volume mesh is presented.

It is shown that the best performance can be achieved when using an orthogonalized hexagonal grid with a distribution of finite dimensions close to uniform.

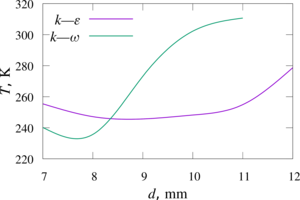

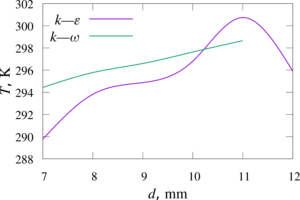

The findings are applied in modeling in the OpenFOAM environment for k−ε and k−ω turbulence models. It is shown that in the above formulation

of the problem, the results obtained demonstrate the general nature of the dependence of the physical parameters on the dimensions of the cold diaphragm.

However, a quantitative difference in the results for the k−ε and k−ω models should be noted. It requires further research and comparison with

experimental data

Keywordsnumerical simulation,

finite volume mesh,

vortex tube,

OpenFOAM

References

- Ranque G.J. Experiments on expantion a vortex with Simultaneous Exhaust of hot air and cold air // J. Phys. Radium. 1994. V. 4. Pp. 112S–114S. (in French)

- Hilsch R. The Use of the Expansion of Gases in a Centrifugal Field as Cooling Process // Review of Scientific Instruments. 1947. V. 18. Pp. 108–113.

DOI: 10.1063/1.1740893

- Khodorkov L., Poshernev N.V., Zhidkov M.A. The vortex tube.a universal device for heating, cooling, cleaning, and drying gases and separating gas mixtures //

Chemical and Petroleum Engineering. 2003. V. 39. Pp. 409–415.

DOI: 10.1023/A:1026336813155

- Ebmeier R., Whitney S., Alugupally S., Nelson M., Padhye N., Gogos G., Viljoen H.J. Ranque–Hilsch Vortex Tube Thermocycler for DNA Amplification //

Instrumentation Science & Technology. 2004. V. 32. Pp. 567–570.

DOI: 10.1081/CI-200029810

- Boucher R.F., Tippetts J.R. Vortex-tube-driven thermo-electricity //

In Sixth triennal international symposium on Fluid Control, Measurement and Visualization, 6th, Sherbrooke, Canada. 2000. Paper 50.

- Westley R. A Bibliography and Survey of The Vortex Tube // The College of Aeronautics. 1957.

- Baz A., Gilheany J., Kalvitas A. Feasibility of vortex tube assisted environmental control of an underwater research habitat // Ocean Eng. 1987. V. 15. Pp. 34–54.

DOI: 10.1016/0029-8018(88)90018-2

- Bruno T.J. Laboratory applications of the vortex tube // Journal of Chemical Education. 1987. V. 64. Pp. 987–988.

DOI: 10.1021/ed064p987

- Gutsol A.F. The Ranque effect // Physics-Uspekhi. 1997. V. 40. Pp. 639–658.

DOI: 10.1070/ PU1997v040n06ABEH000248

- Eiamsa-Ard S., Promvonge P. Review of Ranque–Hilsch effects on vortex tubes // Renewable and Sustainable Energy Reviews. 2008. V. 1. Pp. 1822–1842.

DOI: 10.1016/j.rser.2007.03.006

- Attalla M., Ahmed H., Ahmed M.S., El-Wafa A.A. An experimental study of nozzle number on Ranque–Hilsch counter-flow vortex tube //

Experimental Thermal and Fluid Science. 2017. V. 82. Pp. 381–389.

DOI: 10.1016/j.expthermflusci.2016.11.034

- Hamdan M.O., Al-Omari S.-A., Oweimer A.S. Experimental study of vortex tube energy separation under different tube design //

Experimental Thermal and Fluid Science. 2018. V. 91. Pp. 306–311.

DOI: 10.1016/j.expthermflusci.2017.10.034

- Mikhaylenko C.I. Simulation of the vortex tube: design of a hexagonal mesh for computational experiments in OpenFOAM //

Proceedings of the Mavlyutov Institute of Mechanics. 2016. V. 11. Pp. 112–118. (in Russian)

DOI: 10.21662/uim2016.1.017

- Minishev Sh.R., Mikhailenko C.I. Formation of an unstructured mesh for a vortex tube model in OpenFOAM with Salome //

In the book: Physicochemical hydrodynamics: models and applications. Abstracts of the Second All-Russian Summer School-Conference. 2018. (in russian)

- Koroleva E.N., Mikhailenko C.I. Constructing the geometry of the calculation domain for the vortex tube model by SnappyHxMesh utility of the OpenFOAM software //

In the book: Physicochemical hydrodynamics: models and applications. Abstracts of the Second All-Russian Summer School-Conference. 2018. (in russian).

- Minibaev M.R., Mikhaylenko C.I. Investigation of the influence of boundary conditions in the numerical solution of a vortex tube model //

Multiphase Systems. 2019. V. 14. Pp. 89–100. (in Russian)

DOI: 10.21662/mfs2019.2.013

- Mikhaylenko C.I. Making of a finite-difference mesh and a turbulence model selection for a numerical simulations of a vortex tube in OpenFOAM software //

Journal of Physics: Conference Series. 2020. V. 1677. 012021.

DOI: 10.1088/1742-6596/1677/1/012021

- Mikhaylenko C.I. Vortex tube modelling: outlet parameter dependencies of cold air production // Journal of Physics: Conf. Series. 2019. V. 1158. 032032.

DOI: 10.1088/1742-6596/1158/3/032032

- Adiullin B.R., Mikhaylenko C.I. Influence of the channel length of a vortex tube on the air temperature separation // Journal of Physics: Conf. Series. 2019. V. 1268. 012001.

DOI: 10.1088/1742-6596/1268/1/012001

- Privalov L.Y., Mikhaylenko C.I. The effect of an additional air inlet in the hot outlet area on the overall effectiveness of a vortex tube //

Journal of Physics: Conference Series. 2019. V. 1392. 012019.

DOI: 10.1088/1742-6596/1392/1/012019

- Burazer J.M.; Ćoćić A.S., Lečić M.R. Numerical research of the compressible flow in a vortex tube using OpenFOAM software // Thermal Science.2017. V. 21. Pp. S745–S758.

DOI: 10.2298/TSCI160223195B