Kruglov N.O., Bogdanov D.R., Nasibullayev I.Sh.

Synthesis of an inspection modular robot’s design. Multiphase Systems. 20 (2025) 1. 33–44 (in Russian).

Synthesis of an inspection modular robot’s design

N.O. Kruglov

1,2, D.R. Bogdanov

1 🖂, I.Sh. Nasibullayev

31Mavlyutov Institute of Mechanics UFRC RAS, Ufa

2Ufa State Oil Technical University, Ufa

3Ufa University of Science and Technology, Ufa

Abstract

The paper presents a methodology for designing computer models of mobile robots, and also shows the results of computer simulations

using mathematical algorithms to determine the trajectory of the robot. The methodology includes creating a modular robot design using

the Solidworks design system, creating its computer model in the ROS programming software, and simulating the behavior of the model

in the Gazebo simulation environment. An algorithm for moving a modular wheeled robot consisting of modules with a movable wheel

pair has been developed. The advantage of this algorithm compared to the previous one (with modules with a fixed wheel pair) is that

the slave modules follow strictly along the trajectory of the leading module. This increases the cross-country ability when the robot

moves on a plane bypassing obstacles and increases the accuracy of work (scanning, repair, cleaning, etc.) in the configuration of a pipe

inspection robot. The simulation results showed that the behavior of the robot model corresponds to computational experiments conducted

on the basis of previously developed mathematical models. The technique was applied to the development of a computer model of a

wheeled modular mobile robot. During the simulations, it was found that the presence of movable wheel pairs in the robot modules

allows eliminating deviations in the trajectories of slave modules from the trajectory of the leading module. Taking this into account, a

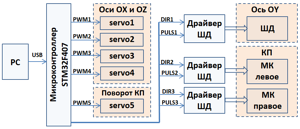

model of a three-link wheeled robot was built based on modules with a movable wheel pair. To check the operability of the assembledmodel and the correctness of the drive installation, a control circuit was assembled based on the STM32F407 Discovery debug board

and stepper motor drivers. The resulting technique can be used to conduct computer experiments to study the kinematics and dynamics

of the developed designs of modular robots in workspaces with a complex topology, for example, in pipelines.

Keywordsmobile modular wheeled robot,

mathematical and computer model,

robot prototype,

ROS,

Gazebo

Article outline

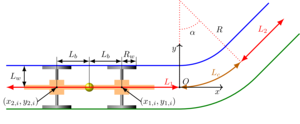

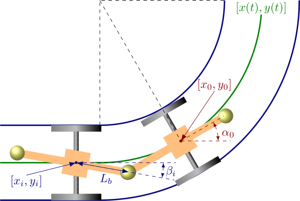

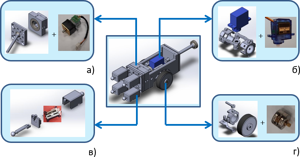

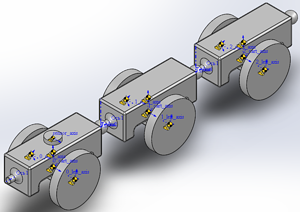

To meet the requirements for inspection robotic systems, it is necessary to perform a set of works, which includes development of the robot module design, synthesis of universal mechanical and information interfaces between modules, as well as development of algorithms for forming the mutual arrangement of modules (robot configurations). Based on the analysis of existing types of robots, a variant of a new design of an inspection mobile wheeled robot was proposed, consisting of modules connected by a ball joint. Each module consists of a trolley and a wheel pair. Two variants of the wheel pair design are considered in relation to the possibility of rotation around the vertical axis - fixed and controlled.

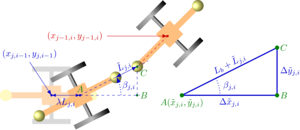

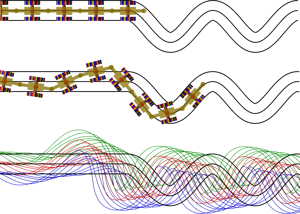

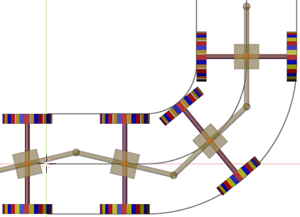

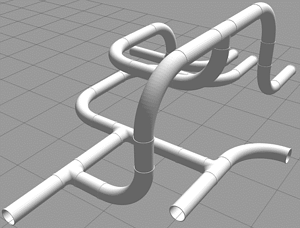

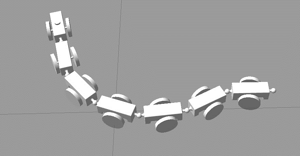

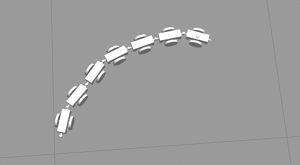

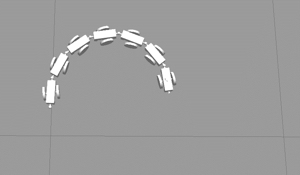

Previously, the authors developed an algorithm for calculating the configuration of a mobile wheeled robot when moving along an arbitrary trajectory with modules that have a fixed wheel pair. It was shown that in this case the trajectories of the slave modules and the leading one differ. In the presented work, a numerical algorithm for calculating the configuration of a robot with modules with controlled wheel pair has been developed. The simulation results showed that by controlling the rotation of the wheel pair, it is possible to achieve the movement of the slave modules strictly along the trajectory of the leading module. To visualize the kinematics of the robot, a script for the Blender Python API was developed.

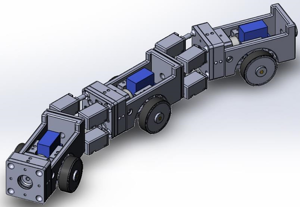

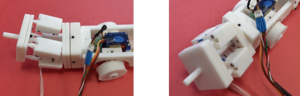

Based on the results of mathematical simulation of the design of a modular wheeled robot, and taking into account the need to ensure spatial reconfiguration of the robot during its movement, the following robot layout was selected: the connection between the modules is performed using a three-axis joint, and to eliminate deviations in the trajectories of the slave and leading modules on curved sections of the trajectory, a rotation of the wheel pair is used. The joint is implemented as a combination of a spherical plain bearing and a rotary hinge, while the change in the position of the modules along two coordinates is carried out by four linear drives, and a stepper motor performs rotation with a reducer located inside one of the mating modules. The movement of the robot is carried out using motor wheels with integrated stepper motors, changing the ratio of rotation speeds or directions of which it is possible to obtain any trajectories. The rotation of the wheel pair is carried out using a system of rods controlled by a servo drive. A prototype robot was assembled from the developed components of the robot design, manufactured on a Form3 3D printer from FormLabs, consisting of 3 modules with motors installed in them.

The simulation of the developed model was carried out with two states of the moving platform: with fixed wheels and controlled. The goal of the simulation was the successful passage of the robot along a circular trajectory without deviation of modules from the trajectory. During the simulations, it was found that the moving wheels platform allows reducing the oscillations of the trajectory of the modules, starting with the second, relative to the trajectory of the first module. Similar results were obtained earlier during the simulation of the mathematical model.

It is planned to continue work in the following areas: correction of mathematical models taking into account the selected design of the robot module, development of a complete dynamic model of the robot, synthesis of the architecture of the control system taking into account its physical implementation, development of the robot information system, experimental verification of modernized mathematical models of the robot and creation of a full-scale test bench with models of pipelines of arbitrary topology.

References

- Ogai H., Bhattacharya B. Pipe Inspection Robots for Structural Health and Condition Monitoring // Intelligent Systems, Control and Automation:

Science and Engineering. 2018. V. 89. P. 213.

DOI: 10.1007/978-81-322-3751-8

- Li H., Li R. Zhang J., Zhang P. Development of a Pipeline Inspection Robot for the Standard Oil Pipeline of China National Petroleum Corporation //

Appl. Sci. 2020. V. 10. P. 2853.

DOI: 10.3390/app10082853

- Tubot LLC, part of TechnoSpark and Sigma Group of Companies. Novosibirsk, Russia.

http://tubot.pro/

- Tatar O., Cirebea C., Alutei A. The Modular Robotic System for In-pipe Inspection / In: Pisla D., Ceccarelli M., Husty M., Corves B. (eds.) // New Trends

in Mechanism Science. Mechanisms and Machine Science. 2010. V. 5. Pp. 583–591.

DOI: 10.1007/978-90-481-9689-0_67

- Min J., Setiawan Y.D., Pratama P.S., Kim S.B., Kim H.K Development and Controller Design of Wheeled Type Pipe Inspection Robot // Proceedings of

the 2014 International Conference on Advances in Computing, Communications and Informatics. 2014. Pp. 789–795.

DOI: 10.1109/ICACCI.2014.6968543

- Enner F., Rollinson D., Choset H. Motion estimation of snake robots in straight pipes // Proceedings – IEEE International Conference on Robotics and

Automation. 2013. Pp. 5168-5173.

DOI: 10.1109/ICRA.2013.6631316

- Mills G.H., Liu J.H.W., Kaddouh B.Y. et al. Miniature Magnetic Robots For In-Pipe Locomotion / In: Montes H., Tokhi M.O., Virk G.S., Armada M., Rodriguez H.,

Fernandez R., Gonzalez de Santos P., Sanchez V. and Silva M. (eds.) // Robotics Transforming the Future: Proceedings of CLAWAR 2018. 2018. Pp. 289–

300.

- Nasibullayev I., Darintsev O., Bogdanov D. (2022) In-Pipe Modular Robot: Configuration, Displacement Principles, Standard Patterns and Modeling /

In: Ronzhin A., Shishlakov V. (eds.) // Electromechanics and Robotics. Smart Innovation, Systems and Technologies. 2022. V. 232. Pp. 85–96.

DOI: 10.1007/978-981-16-2814-6_8

- Павловский В.Е., Петровская Н.В. Исследование динамики движения цепочки «Робопоезд». Уравнение движения, частные решения. М.: ИПМ,

2005. 31 с.

Pavlovsky V.E., Petrovskaya N.V. Study of the dynamics of the ”Robotrain“ chain motion. Equations of motion, particular solutions. Preprints of the

Keldysh Institute of Applied Mathematics. 2005. 31 p. (in Russian).

- Евграфов В.В., Павловский В.Е., Петровская Н.В. Исследование динамики движения цепочки «Робопоезд». Управляемое движение. М.: ИПМ,

2005. 31 с.

Evgrafov V.V., Pavlovsky V.E., Petrovskaya N.V. Study of the dynamics of the movement of the chain ”Robotrain“. Controlled motion. Preprints of the

Keldysh Institute of Applied Mathematics. 2005. 31 p. (in Russian).

- Darintsev O.V., Nasibullayev I.S., Bogdanov D.R. Inspection of Pipelines of Complex Topology Using an Adaptive, Scalable Multi-segment Mobile

Robot / In: Yuschenko A. (eds.) // Modern Problems of Robotics. MPoR 2020. Communications in Computer and Information Science. 2021. V. 1426.

Pp. 137–150.

DOI: 10.1007/978-3-030-88458-1_11

- Аюпов В.В. Исследование маневренных свойств автопоездов на основе системного подхода: монография. Пермь: Изд-во ФГБОУ ВПО Пермская

ГСХА, 2012. 96 с.

Ayupov V.V. Study of maneuvering properties of road trains based on a systems approach: monograph. Perm: Publishing house FGBOU VPO Perm

State Agricultural Academy, 2012. 96 p. (in Russian).

- Nasibullayev I., Darintsev O. Algorithms for Planning Trajectory of a Modular Wheeled In-Pipe Robot / In: Ronzhin A., Savage J., Meshcheryakov R.

(eds.) // Interactive Collaborative Robotics. ICR 2024. Lecture Notes in Computer Science. 2024. V. 14898. Pp. 251–264.

DOI: 10.1007/978-3-031-71360-6_19

- RoboDK homepage.

https://robodk.com/pricing

(дата обращения: 30.01.2025).

- Rohmer E., Singh S, Freese M. V-REP: A versatile and scalable robot simulation framework // Proceedings of the IEEE/RSJ International Conference

on Intelligent Robots and Systems. IEEE/RSJ International Conference on Intelligent Robots and Systems. 2013. Pp. 1321–1326.

DOI: 10.1109/IROS.2013.6696520

- RoboLogix homepage.

https://www.robologix.com/

(дата обращения: 30.01.2025).

- SimSpark homepage.

https://robocup-sim.gitlab.io/SimSpark/index.html

(дата обращения: 30.01.2025).

- Michel O. Webots: Professional Mobile Robot Simulation // Journal of Advanced Robotics Systems. 2004. V. 1, No. 1. Pp. 39–42.

DOI: 10.5772/5618

- Gazebo Sim homepage.

http://gazebosim.org/home

(дата обращения: 30.01.2025).

- ROS — Robot Operating System homepage.

http://www.ros.org

(дата обращения: 30.01.2025).

- Salome-Meca homepage.

https://code-aster.org/

(дата обращения: 30.01.2025).

- FreeCAD homepage.

https://www.freecad.org/

(дата обращения: 30.01.2025).

- Solidworks homepage.

https://www.solidworks.com/

(дата обращения: 30.01.2025).

- Blender homepage.

https://www.blender.org/

(дата обращения: 30.01.2025).

- Andrade A., Alvarez Cedillo J., Lozada J.H., Zarate I.R. Robotic Arm Control With Blender 1 // Journal of Emerging Trends in Computing and Information

Sciences. 2013. V. 4, No. 4. Pp. 382–386. .

- Matsuno F. et al. Development of Tough Snake Robot Systems / In: Tadokoro S. (eds.) // Disaster Robotics. Springer Tracts in Advanced Robotics. 2019.

V. 128. Pp. 267–326.

DOI: 10.1007/978-3-030-05321-5_6

- Sawabe H., Nakajima M., Tanaka M., Tanaka K., Matsuno F. Control of an articulated wheeled mobile robot in pipes // Advanced Robotics. 2019.

V. 33(20). Pp. 1072–1086.

DOI: 10.1080/01691864.2019.1666737

- Liu Ch., Whitzer M., Yim M. A Distributed Reconfiguration Planning Algorithm for Modular Robots // IEEE Robotics and Automation Letters. 2019. V. 4.

Pp. 4231-4238.

DOI: 10.1109/LRA.2019.2930432

- Hauser S., Mutlu M., Léziart P.-A., Khodr H., Bernardino A., Ijspeert A.J. Roombots extended: Challenges in the next generation of self-reconfigurable

modular robots and their application in adaptive and assistive furniture // Robotics and Autonomous Systems. 2020. V. 127. P. 103467.

DOI: 10.1016/j.robot.2020.103467

- Pfotzer L., Ruehl S., Heppner G., Roennau A., Dillmann R. KAIRO 3: A modular reconfigurable robot for search and rescue field missions // IEEE

International Conference on Robotics and Biomimetics (ROBIO 2014), Bali, Indonesia. 2014. Pp. 205–210.

DOI: 10.1109/ROBIO.2014.7090331

- SolidWorks to URDF Exporter.

https://wiki.ros.org/sw_urdf_exporter

(дата обращения 30.01.2025).

- Export a SolidWorks Assembly to URDF.

https://wiki.ros.org/sw_urdf_exporter/Tutorials/Export%20an%20Assembly

(дата обращения 30.01.2025).

- Gazebo plugins in ROS.

https://classic.gazebosim.org/tutorials?tut=ros_gzplugins

(дата обращения 30.01.2025).

- Библиотека move_base.

Library move_base.

https://wiki.ros.org/move_base

(дата обращения 30.01.2025).

- Библиотека Gazebo Dashboard.

Library Gazebo Dashboard.

https://app.gazebosim.org/dashboard

(дата обращения 30.01.2025).

- Туровский Я.А., Харченко С.С., Мещеряков Р.В. и др. Алгоритмическое обеспечение интерфейса управления робот-человек при выделении

зрительных вызванных потенциалов на основе многомерного индекса синхронизации // Известия ЮФУ. Технические науки. 2020. № 1(211).

С. 66–78.

Turovsky Y.A., Kharchenko S.S., Meshcheryakov R.V. et al. Algorithmic support of the interface of management of robot-human with the steady state

visual evoked potentials based on the multivariate synchronization index // Izvestiya SFedU. Engineering Sciences. 2020. No. 1(211). Pp. 66–78 (in

Russian)

DOI: 10.18522/2311-3103-2020-1-66-78.