Nasibullayev I.Sh., Nasibullaeva E.Sh., Darintsev O.V.

Study of fluid flow through a channel deformed by piezoelement.

Multiphase Systems. 13 (2018) 3. 1–10.

Study of fluid flow through a channel deformed by piezoelement

Nasibullayev I.Sh., Nasibullaeva E.Sh., Darintsev O.V.

Mavlutov Institute of Mechanics, UFRC RAS, Ufa

Abstract

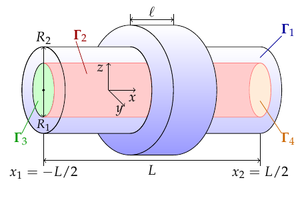

The flow of a liquid through a tube deformed by

a piezoelectric cell under a harmonic law is studied in this paper. Linear deformations

are compared for the Dirichlet and Neumann boundary conditions on the contact surface

of the tube and piezoelectric element. The flow of fluid through a deformed channel

for two flow regimes is investigated: in a tube with one closed end due to deformation

of the tube; for a tube with two open ends due to deformation of the tube and

the differential pressure applied to the channel. The flow rate of the liquid is calculated

as a function of the frequency of the deformations, the pressure drop and the physical

parameters of the liquid.

Keywordshydrodynamics,

hydrodynamic resistance,

piezoelement,

linear elasticity,

finite element method

Article outline

Purpose: the development of a three-dimensional

computer model of fluid flow in a channel with a hydrodynamic resistance, where the form of

the hydro resistivity varies according to the periodic law and is determined by the

deformation of the tube by the piezoelectric element.

Methodology: the Lame equations were solved by the finite element method in the FreeFem ++

package. The equations of hydrodynamics were discretized in time according to the Euler

scheme and solved by the finite element method in the FreeFem ++ package; The solution of the

nonlinear problem was found by Picard iterations.

The findings of research:

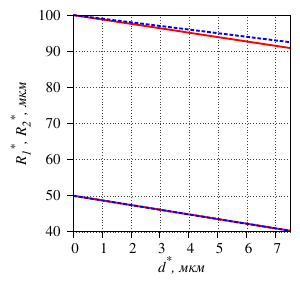

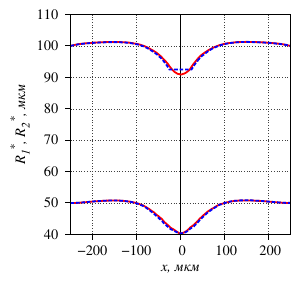

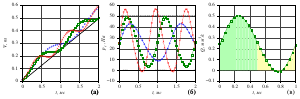

- the interchangeability of the Neumann and Dirichlet boundary conditions is shown: by

selecting the piezoelectric element pressure on the outer part of the tube, one can obtain the

same deformation of the inner part of the tube as when setting the displacement of the contact

surface inwards by a define value (the dependence is linear);

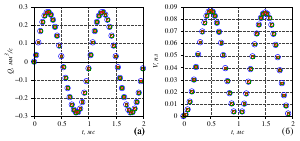

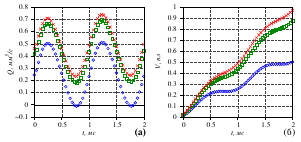

- studied two fluid flow regime in the deformed tube: the tube inlet is closed, the

flow induced tube deformation; both ends are open, the flow is induced both by the

deformation of the tube and by the differential pressure applied to the layer. The first regime

allows one to test the computer model, and the second regime allows one to offer a liquid

dosing mechanism controlled by two parameters: the piezoelement compression rate and the

differential pressure;

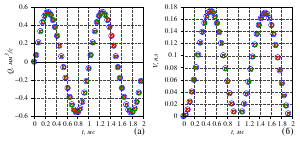

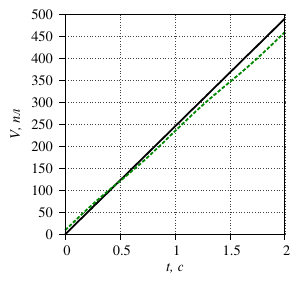

- it is found that the fluid flow rate depends on the compression frequency of the

piezoelectric element and, if there is no pressure drop, does not depend on the physical

parameters of the fluid. This theoretically makes it possible to implement a hydraulic

microdrive with a linear ”mechanical“ (consumable) characteristic;

- under the influence of the pressure drop, a constant component inversely proportional to

the viscosity of the liquid is added to the periodic component of the fluid flow;

- it is shown that one can obtain a flow regime corresponding to the droplet extrusion

by selecting parameters (frequency, pressure drop). The volume of the droplet squeezed out

during the period decreases with increasing frequency.

Originality/value: The proposed computer model describing the fluid behavior in

microchannels using piezoelectric drives is the first step in

developing a theoretical basis for creating microdrives and executive micromechanisms.

References

- Bruus H. Theoretical microfluidics. Lecture notes third edition.

MIC Department of Micro and Nanotechnology Technical University of Denmark. 2006.

URL: http://homes.nano.aau.dk/lg/Lab-on-Chip2008_files/HenrikBruus_Microfluidics%20lectures.pdf

(дата обращения: 10.04.2018).

- Stroock A.D., Dertinger S.K.W., Ajdari A. et al. Chaotic Mixer for

Microchannels // Science. 2002; Vol. 295(5555). Pp. 647–651.

(DOI: 10.1126/science.1066238)

- Насибуллаев И.Ш. Разработка компьютерной модели основного элемента агрегата дозирования топлива //

Вычислительные технологии. 2016. Т. 21, № 2. С. 26–41.

(http://www.ict.nsc.ru/jct/annotation/1724)

- Насибуллаев И.Ш., Насибуллаева Э.Ш., Денисова Е.В. Динамика течения жидкости

в технических системах с жиклерами // Известия Уфимского научного центра РАН. № 4. 2015. С. 20–25.

(http://sciencerb.ru/vyp/4_2015/20-25.pdf)

- Насибуллаев И.Ш., Насибуллаева Э.Ш. Влияние температуры на динамику течения жидкости

в технических системах с жиклерами // Труды Института механики им. Р.Р. Мавлютова

Уфимского научного центра РАН. 2016. Т. 11, № 1. С. 1–9.

(DOI: 10.21662/uim2016.1.001)

- Насибуллаев И.Ш., Насибуллаева Э.Ш. Течение жидкости через систему связанных элементов

технического устройства типа труба–гидросопротивление–труба // Труды Института

механики им. Р.Р. Мавлютова Уфимского научного центра РАН. 2016. Т. 11, № 2. С. 141–149.

(DOI: 10.21662/uim2016.2.021)

- Насибуллаев И.Ш., Насибуллаева Э.Ш. Течение жидкости через гидросопротивление с

динамически изменяемой геометрией // Труды Института механики им. Р.Р. Мавлютова

Уфимского научного центра РАН. 2017. Т. 12, № 1. С. 59–66.

(DOI: 10.21662/uim2017.1.009)

- Ландау Л., Лифшиц Е.М. Теоретическая физика. Т. 7. Теория упругости. М.: Наука, 1987. 248 с.

- Hecht, F. New development in FreeFem++ // J. Numer. Math. 20 (2012), no. 3–4, 251-–265. 65Y15.

(DOI: 10.1515/jnum-2012-0013)

- Ландау Л., Лифшиц Е.М. Теоретическая физика. Т. 6. Гидродинамика. М.: Наука, 1988. 736 с.

- Белоусов К.И., Евстрапов А.А., Кухтевич И.В., Посмитная Я.С.

Основы нанотехнологий. Часть 1. Микро- и нанотехнологии для биологических и медицинских

исследований. Часть 2. Капельная микрофлюидика: Учеб. пособие. СПб: Университет ИТМО, 2015. 56 с.

(http://books.ifmo.ru/file/pdf/1839.pdf)